With over 40 years of experience in custom molded fiberglass, Arrowhead has developed a deep understanding of thermoset materials and advanced molding techniques. We’ve partnered with companies across a wide range of industries to produce durable, cost-effective fiberglass components that meet the highest performance and quality standards.

Our expertise in fiberglass molding is backed by engineering and design support, low-cost tooling, and access to a wide variety of innovative composite materials. Whether you need small or large production runs, we offer flexible manufacturing solutions that deliver consistent results and meet your exact specifications.

We specialize in several closed molding processes for fiberglass, including:

-

Resin Transfer Molding (RTM)

-

RTM Lite

-

Closed Cavity Bag Molding (CCBM)

These processes are ideal for companies requiring custom molded fiberglass parts with smooth surfaces on both sides, consistent wall thicknesses, and the capacity for high-volume production.

For projects requiring extra-large parts, lower production volumes, or molded-in inserts, we offer proven open molding processes like:

-

Fiberglass spray-up molding

-

Fiberglass hand lay-up molding

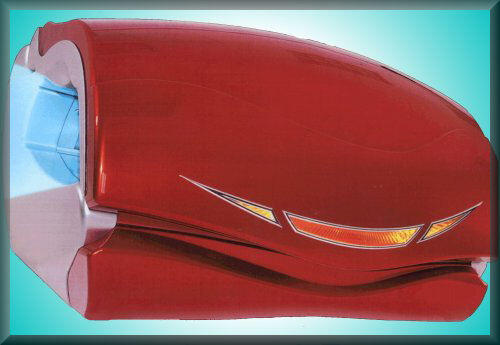

Our fiberglass molding capabilities allow us to create complex shapes, including compound curves and lightweight yet high-strength parts. We also offer molded-in color options and paintable surfaces to match your aesthetic or functional needs. All of our molding methods use cost-efficient tooling and are designed to meet or exceed industry requirements—including compliance with FMVSS 302 flammability standards.

If you’re looking for a reliable partner for custom molded fiberglass components, Arrowhead has the experience, equipment, and flexibility to bring your ideas to life.